FEEDING TECHNOLOGY

DEPRAG’s advanced feeding technology ensures the accurate, timely delivery of screws, pins, nuts, and other components during both manual and automated assembly operations. Engineered for flexibility and precision, it guarantees enhanced productivity across applications.

Overview

In high-performance assembly processes, the precise and timely delivery of fasteners is crucial. DEPRAG’s feeding technology supports both manual and stationary use, offering reliable component orientation and positioning. Whether it’s screws, rivets, washers, or o-rings, our systems are built to handle symmetrical and asymmetrical parts with consistent efficiency. Standard or customized, DEPRAG feeders enhance uptime and streamline your production flow.

Features

- Manual & Stationary Compatibility: Suitable for various assembly setups

- Versatile Component Handling: Supports screws, nuts, pins, rivets, washers, o-rings, and more

- Reliable Orientation: Ensures precise positioning of symmetrical and asymmetrical parts

- Custom & Standard Systems: Ready-to-use or fully tailored solutions available

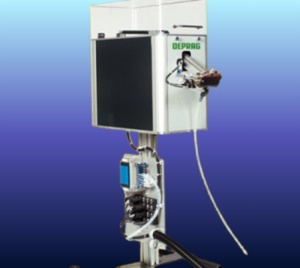

- Multiple Feeding Mechanisms: Vibratory bowl, sword (segment), and tape-on-reel options

- Flexible Transport Options: Feedhose delivery or pick-and-place configurations

- High System Reliability: Proven performance across industrial environments

Specifications

- Component Types: Screws, nuts, rivets, pins, washers, o-rings, etc.

- Fastener Sizes: Supports M1 to M16 standard sizes

- Feeding Systems: Vibratory bowl, sword segment, tape-on-reel

- Delivery Modes: Feedhose-based or pick-and-place system

- Applications: Manual stations, robotic arms, automated lines

- Customization: Fully configurable for client-specific needs