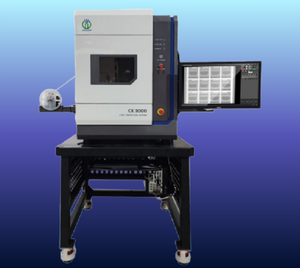

UNICOMP Desktop X-RAY Inspection Machine – CX3000

Compact Desktop Solution for Precision Inspection The UNICOMP CX3000 is a desktop X-ray inspection machine designed for evaluating internal defects in electronic components and PCBA welding quality. With auto-measuring capabilities and support for data and graphic outputs, it provides a comprehensive and user-friendly inspection solution.

Overview

The CX3000 supports measurements of distance, angle, diameter, polygon shapes, PTH (Plated Through Hole) filling rate, and more. It offers real-time display of working data including voltage, current, angle, and date, all within a visual navigation window. The system also features automatic conveying for reel-to-reel components, ensuring smooth and efficient operation.

Features

- Internal Defect Inspection: Ideal for electronic components and PCBA welding quality checks.

- Auto-Measuring & Output: Automatically measures key dimensions with data and graphic output support.

- Measurement Capabilities: Distance, angle, diameter, polygon, PTH filling rate, etc.

- Real-Time Data Display: Monitors voltage, current, angle, and date during operation.

- Visual Navigation: Intuitive visual window navigation system for ease of use

- Automatic Conveying: Supports reel-to-reel component handling for streamlined processes.

- User-Friendly: Designed for easy operation in desktop environments.

Specifications

- Inspection Type: X-ray inspection of electronic components and PCBA

- Measurement Functions: Distance, angle, diameter, polygon, PTH filling rate

- Data Display: Real-time monitoring of voltage, current, angle, date

- Interface: Visual navigation windows

- Material Handling: Automatic reel-to-reel conveying

- Operation: Desktop, user-friendly interface