Yamaha YSi SP

- 1-head solution to perform various inspections with a single head

- Achieves high-accuracy high-speed inspections using 3D+2D inspection, image resolution switch-over and more

- A thorough and extensive machine-to-machine (M2M) solution

- Statistical Process Control (SPC) for diverse statistical processing

- Optional features to enable handling various products

OMRON 3D SPI – VP - 01G (CKD)

- Solder paste inspection machines ( SPI ) can analyze and optimize printing conditions

- The VP-01G prevents printing defects by detecting faults and optimizing printing conditions

- A camera captures solder paste images with a stripe pattern light using 3D projectors that are positioned diagonally and face downwords

- FOR FACTORY AUTOMATION:

- Auto Program Launch

- Bad mark Communication

- Closed loop

- AOI Link

- FOR QUALITY & PRODUCTIVITY

- SPC

- Line quality Management

- X-bar-R / X-bar S Display

- Log Information Output

VISCOM Lab – to – Fab – iX7059 One

- iX7059 One apart is its versatility. With X-ray Inspection capabilities spanning 2D, 2.5D, and 3D, it is equipped to handle the diverse needs of modern manufacturing

- From single semiconductor devices with intricate internal structures to leadframe applications requiring comprehensive analysis, this system delivers flexibility from standalone to unparalleled 100 % inline inspection for production performance across the board

- This system delivers unrivaled image quality down to an astonishing 1μm resolution. From intricate semiconductor devices to complex leadframe applications, every detail is captured with breathtaking clarity

VISCOM Inline 3D Inspection of Heavy Inspection Objects with Maximum Precision – iX7059

- Large, heavy, and solid assemblies – whether encased or as complete models – require 100% quality assurance, depending on the area of application

- With its iX7059 product line, Viscom is setting a new standard for fast, high-precision inline X-ray inspection. The special transport system enables seamless handling of inspection objects on workpiece carriers or in soldering frames with a weight of up to 40 kg – a unique feature that offers huge advantages for trending segments such as e-mobility, new energies, and telecommunications

- Powerful X-rays with 130 kV or optionally 160 kV

- Fast inspection program creation thanks to 3D analysis and an IPC-compliant AXI inspection library. Maximum inspection program optimization through integrated verification

VISCOM 3D AXI Pioneering 3D X-ray Inspection for Flat Assemblies

- The compact iX7059 PCB Inspection or iX7059 PCB Inspection XL 3D AXI system also provides high-precision, reliable inspection of soldering defects such as head-in-pillow and pores in BGA and LGA components.

- The iX7059 PCB Inspection XL with extended longboard option comes into play for especially large PCB assemblies measuring up to 1,600 mm – this solution is ideal for server boards, LEDs, semiconductors and 5G electronics.

- Outstanding inspection performance for SMD and THT solder joints as well as exact measurement of voids deliver 100% quality assurance in modern SMT production, so that hidden defects can be detected even when complex assemblies cause massive shadowing effects.

- Unbeatably fast dynamic image acquisition concept Evolution 4 or optionally 5 for even more speed and the highest throughput.

VISCOM 3D Reliable Inspection of Power Semiconductors – iX7059

- The new iX7059 Module Inspection offers seamless and reliable quality assurance for this purpose. The fully automatic 3D X-ray system with integrated computed tomography is distinguished by easy-to-classify, accurate layer inspection images and a large inspection scope.

- The X-ray system offers flawless handling of frame-based power modules or components on workpiece carriers. The iX7059 Module Inspection is compact and can be easily integrated into a line. There it fulfills - intelligently networked - all smart factory requirements.

- Intelligent checking of voids for flawless heat dissipation. Easy to classify, accurate layer test images.

- Additional vertical slices for optimum analyses and dependable verification.

- Fast inspection program creation thanks to 3D analysis and an IPC-compliant AXI inspection library.

VISCOM 3D AXI/AOI Ultra-fast Handling Meets Outstanding Image Quality– iX7056 II

- The X7056-II's state-of-the-art X-ray technology ensures precise inspection of high-end electronics. The inline X-ray system has won five international awards for its extremely high throughput and outstanding image quality.

- The option to also integrate AOI inspection within the system and to perform combined inspections is a special feature of the X7056-II – an efficient, space-saving highlight that provides fast and comprehensive inspection results. Ultra-thorough inspection of single or double-sided electronic assemblies.

- Three different flat panel detector sizes for scalable throughput.

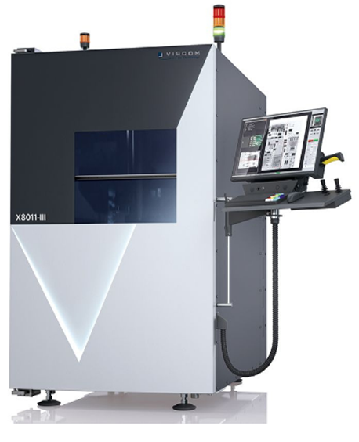

VISCOM 3D MXI Quality inspection for the very best reliability, detail and innovation – X8011-III

- The Viscom X-ray system X8011-III is designed as a team player for individual and reliable use for 2D and 3D X-ray inspection.

- Its innovative and simple system operation, the system can be used for manual and automatic X-ray inspection of components, assemblies during production, quality assurance and development – thereby making a sustainable and result-oriented contribution to cost optimization, process reliability and increased product quality.

- A flexible system configuration of all Viscom X-ray tubes up to 200kV. Optimum magnification and high-end image quality. The use of high-resolution, digital flat-screen detectors.

- Rapid axis and module change via EasyClick method. Upgradable with Viscom-native computed tomography.

- Reliable inspection in 2D and 3D in the shortest cycle time. Intuitive user interface for manual and automatic use.

UNICOMP X-RAY Inspection Machine – AX8200

- BGA, CSP, LED, Flip Chip, Semiconductor, Battery Industry, Small Metal Casting, Electronic Connector Module, Aerospace Components , Photovoltaic Industry, Other Special Industries.

- Large Size Inspection Table Laser Locator for Precise Location.

- 24 inches FHD Interactive Touch LCD Display.

- Accurate Control, CNC Programming Automatic Positioning.

- FPD 60 degrees Tilting Inspection.

- Fingerprint Access Management System.

- Real-time Monitoring of Radiation.

UNICOMP X-RAY Inspection Machine – AX7900

- 90KV 5μm X-ray tube, FPD Detector. Multi-function workstation, XY multi-axis movement standard with ±60° tilt motion (option). Z axis movement for x-ray tube & FPD to increase/decrease magnification/FOV.

- Convenient target point positioning system. Multi-function DXI image processing system with XY programming for multiple image inspection routines. Max.

- Loading area 420mm x 420mm , max. detection area 380 x 380mm, with ~300X System Magnification.

UNICOMP X-RAY SMD CHIP COUNTING SYSTEM – CX7000L

- Fingerprint Access Management and Real-time Monitoring of Radiation.

- Anti-interference Counting Algorithm.

- Embedded Sensors for Identifying Reels.

- AI Technology for Counting Different Components.

- Intelligent QR Reading System.

- Full Anti-pinch Hand System.

UNICOMP Desktop X-RAY Inspection Machine – CX3000

- Internal defects of electronic components, PCBA welding quality Auto-measuring and Support Data/Graphic Output.

- Support Measuring Distance, Angle, Diameter, Polygon, PTH filling rate, etc.

- Real-time Displayingthe Working Data of Voltage,Current,Angle, Date, etc.

- Navigation inVisual Windows.

- Automatic conveying of reel to reel components, Easy Operation and User Friendly.